-

MC´s Know-how for Stuttgart 21 - the Bossler tunnel

For the Stuttgart 21 megaproject, MC was able to contribute both its expertise and its bespoke product systems for tunnel construction from its Tunnelling Field of Expertise, all very much to the satisfaction of its clients.

MC´s Know-how for Stuttgart 21 - the Bossler tunnel

Stuttgart - Deutschland

The Stuttgart-Ulm project, also known as Stuttgart 21 (S21 for short), is one of the largest infrastructure undertakings in the recent history of the Federal Republic of Germany. In future, it will add the metropolitan region in Swabia to the high-speed “Magistrale for Europe” rail link, while also serving as an important hub within the North-South and East-West Trans-European Transport Networks (TEN-T) criss-crossing Central Europe.

A German megaproject

With a spend of around 8 billion euros, the transformational Stuttgart 21 transport and urban development project will greatly benefit the local region through the creation in the near future of a major hub in the national – and international – railway network. More than 100 km of new, fast railway track, three new stations and an intelligent traffic management concept will set new standards in domestic German and European rail transport going forward. And there will also be major benefits on the urban planning side: About one square kilometre of current or former track sections on the edge of Stuttgart's city centre are to be put to good use in the project, extending the downtown area by around 40 percent. The client and developer overseeing this project is Deutsche Bahn. The Federal Republic of Germany, the State of Baden-Württemberg, Stuttgart’s integrated public transport authority VRS, the state capital Stuttgart, the airport company Flughafen Stuttgart GmbH and the European Union are also participating in the financing of the project. Seen in its entirety, S21 is made up of the following subprojects: The lowering of Stuttgart main station, construction of the Stuttgart railway ring track and construction of a new Stuttgart-Ulm line, which includes several tunnels. MC was significantly involved in the latter two measures in particular.

MC’s expertise in mechanical tunnel excavation in high demand

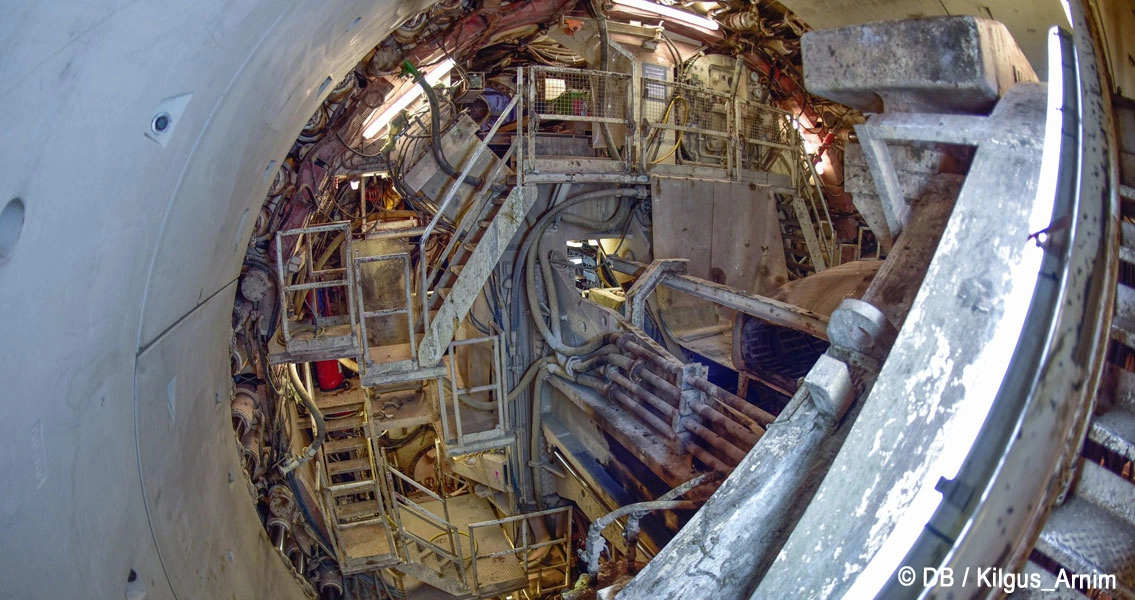

The heading operation with lining segment installation was conducted using a full-thickness-cutting shield TBM featuring multi-mode earth pressure balance (EPB) for face support. The Bossler Tunnel passing through the Albaufstieg (Swabia’s Jura uplands) was only one of several major tunnel projects involving MC that were mechanically excavated. Various MC technologies and product systems were used in all the tunnel construction projects, including special products for soil conditioning, superplasticisers for lining segment production, injection systems for waterproofing the tunnels and, last but not least, a completely new, cement-free annular gap backfill grout – an innovation successfully developed in harness with the special-purpose consortium ARGE ATCOST 21.

In the large tunnel project, the Albaufstieg, two tunnel tubes each with a diameter of 10.87 meters and a cover of up to 280 meters were excavated in the new Boßler tunnel on the new Wendlingen – Ulm line on Aichelberg. With a length of 8,806 meters, it will be one of the longest railway tunnels in Germany.

© MC-Bauchemie 2026

Efficient heading with soil conditioners from MC

In the case of the Bossler Tunnel passing through the Jura slope of the Albaufstieg in the third section of the Stuttgart-Ulm project, the rock encountered during heading operations was of very low strength in places and featured fault zones with water ingress. A closed shield machine was deployed on all three tunnel sections, with the excavated soil being used to support the working face as the TBM advanced. As mentioned above, the tunnel boring method is based on EPB technology, which is applied especially in difficult geological formations and in inner-city areas. The MC-Montan Drive product series from MC was used as the soil conditioning agent for all the mechanically excavated tunnels of the new Stuttgart-Ulm line. And the MC-Montan Device CT (Cell Tube) foam generator was employed for the efficient production of a high-quality and durable foam, enabling operations to continue with minimal interruption, minimal maintenance and minimal specific consumption values.

Ideal lubrication

The most widely used soil conditioning agent was MC-Montan Drive FL 04 (Foam Liquid), an environmentally compatible and readily biodegradable foam concentrate with a defined proportion of clay additive. The product is ideally suited for soil conditioning in EPB tunnelling as well as in rock formations with a high clay content and a high likelihood of clogging. Economical in use, MC-Montan Drive FL 04 prevents deposition and agglomeration and increases the lubrication effect by dispersing the clay minerals. By repelling spoil and preventing accumulation at the cutter head, the agent also reduces TBM power consumption and cutting tool wear. Thus the soil conditioning solutions from MC were able to increase heading efficiency in all three of the tunnel projects mentioned as well as satisfy strict cost-efficiency requirements.

Summary

For the Stuttgart 21 megaproject, MC was able to contribute both its expertise and its bespoke product systems for tunnel construction from its Tunnelling Field of Expertise, all very much to the satisfaction of its clients. In cooperation with planning engineers and construction companies, the tunnel experts at MC also developed innovative solutions optimally adapted to the various requirement profiles and challenges encountered on site, thus further facilitating the smooth progress of the tunnel projects.

-

Name

MC´s Know-how for Stuttgart 21 - the Bossler tunnel

-

Country

Stuttgart - Deutschland, 2021

-

Fields of Expertise

-

Categories

-

Nyheder

Klik her for at gå til vores nyhedssektion.

-

MC-Pedia

I vores MC-Pedia finder du tekniske artikler om forskellige emner udelukkende skrevet af vores specialister.

-

Magasin

Få vores seneste numre af vores kunde- og medarbejdermagasin MC aktiv.

-

Downloads

Du kan se alle relevante datablade for vores produkter samt brochurer om vores firma, ekspertise og produktkategorier her.

-

Referencer

Klik her for at komme til vores bibliotek med referenceprojekter til alle typer applikationer.

-

Karrierer

Klik her for at gå til MC Career.

-

Kontakt

Klik her for at gå til vores kontaktsektion.